Technological development related to decommissioning

(2020)

QHow can tritium taken up by animals and plants be measured?

ATritium incorporated into animals and plants exists in tissue-free water tritium (TFWT) and organically bound tritium (OBT). It is important to separate and measure TFWT and OBT, which have different movements due to metabolism, when considering the effects on the living body. In order to measure tritium that emits weak beta rays with a liquid scintillation detector, a step of separating TFWT and a step of converting OBT to tritium water are required. JAEA has succeeded in significantly reducing the time required for these processes.

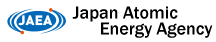

Establishing emergency-monitoring methods is an important tool for assessing environmental impacts. The hydrogen isotope tritium (3H) exists in the environment in water and organic substances as organically bound tritium (OBT) and as tissue-free water tritium (TFWT) (Fig.1).

Fig.1 Chemical state of tritium in a living body

Tritium exists as tissue free water tritium (TFWT) and organically bound tritium (OBT) in a body.

To measure the beta particle emission and thus the tritium concentration of a sample, samples need to be converted to tritiated water. TWFT can be removed by a drying process; to recover OBT, processes need to be performed to convert it into TFWT, such as combustion. The Ministry of Education, Culture, Sports Science and Technology’s (MEXT’s) manual has been established as the standard measurement scheme of tritium in Japan. However, the pretreatment process requires time and technical ability, thus hindering the number of tests possible and decreasing the reliability of the measurements.

Therefore, to increase the reliability and number of possible measurements, a simple pretreatment method was developed with a detection limit of 1 Bq per kilogram of raw flounder using flounder off the coast of Fukushima Prefecture.

In this simple, two-step process, a freeze-drying pretreatment process is first used to separate free water in the tissue; combustion is then used to turn organic matter into water.

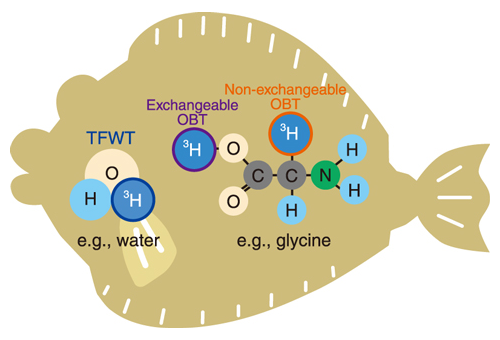

Fig.2 (a) Freeze dryer and (b) rapid combustion vessel

(a) The freeze dryer was used to process flounder samples for analysis. (b) The dried flounder samples were then burned in the rapid combustion vessel to decompose organic matter into water, allowing the OBT to be collected.

In the freeze-drying process (Fig.2(a)), one side of the sample was set to approximately 1 cm like cubes to increase the surface area and shorten the drying time. This allowed the drying process, originally taking approximately two weeks, to be completed in four days.

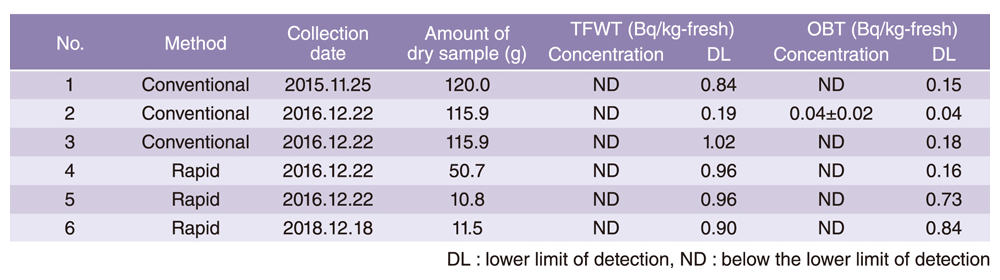

In the second step, the dried samples were combusted using a rapid combustion vessel (Fig.2(b)), which has rarely been used in Japan. This device allows for fast processing when there are few samples. Further, the water recovery, cooling, heating, and degassing processes from the vessel were simplified by focusing on the process of separating excess gas, thus it was confirmed that allowing the gas generated by combustion to be collected simultaneously without separating. These process improvements allowed the process to be shortened from approximately one week to approximately one day. In this system, burning a 10-g sample of dried flounder sample yields 5 ml of combustion water. Duo to the lower limit of detection for tritium measured using a liquid scintillation detector and the weight loss due to drying, the obtained lower limit of detection of OBT in biological samples was 1 Bq/kg raw (Table 1).

Table 1 Tritium concentration of collected flounder

The concentrations were determined by the conventional and rapid methods with a detection limit of 1 Bq/kg. No tritium was detected.

To confirm its reliability, the developed rapid analysis method was used in an annual analysis comparison sponsored by OBT workshop.

At the request of the International Atomic Energy Agency (IAEA), technical guidance was given to IAEA engineers regarding the developed procedure and the installation and operation of the pretreatment equipment.

Related articles

- Is it possible to visualize radiations? Also, is there a way to understand the situation of contamination inside the Fukushima Daiichi NPS buildings?

- What is a cesium ball?

- What happened to the inside of the reactor pressure vessel and storage vessel after the accident?

- What information is needed to safely retrieve fuel debris?