Information on treated water and decommissioning

(2023)

QOn performing fuel debris retrieval work*1, what kind of measures are taken to ensure the safety of workers?

AIn fuel debris retrieval work, it is important to monitor the concentrations of airborne radioactive microparticles (α-aerosols*2) to prevent internal exposure of workers. Radiation dose rates inside the primary containment vessels (PCV) are extremely high due to fuel debris remaining inside, and the humidity is nearly 100%. Therefore, conventional dust monitors for α-rays cannot be casually applied.

Considering the actual conditions of the retrieval work sites, JAEA developed the In-situ Alpha Air Monitor (IAAM), a system to measure highly concentrated α-aerosols in real time (Figure 1). JAEA demonstrated that the IAAM reliably functions in highly humid environments, and is able to measure the radioactivity of α-aerosols that is concentrated more than 30 times the estimated radioactivity concentration inside the PCV of the Fukushima Daiichi Nuclear Power Station (1F).

In situ monitoring of α-aerosols that may scatter during fuel retrieval work would greatly help in taking safety measures for workers. JAEA plans to improve the IAAM and implement it at the decommissioning sites of the 1F to ensure safe decommissioning work.

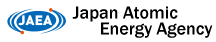

Figure 1 Schematic illustration of fuel debris retrieval work

Highly concentrated α-aerosols will be generated during fuel debris retrieval, since the debris needs to be cut into smaller pieces to take out of the primary containment vessels (PCV). The key to ensure safety of the decommissioning work is containment and monitoring of the aerosols, and the IAAM enables measuring highly concentrated α-aerosols in high-humidity high-radioactivity environments.

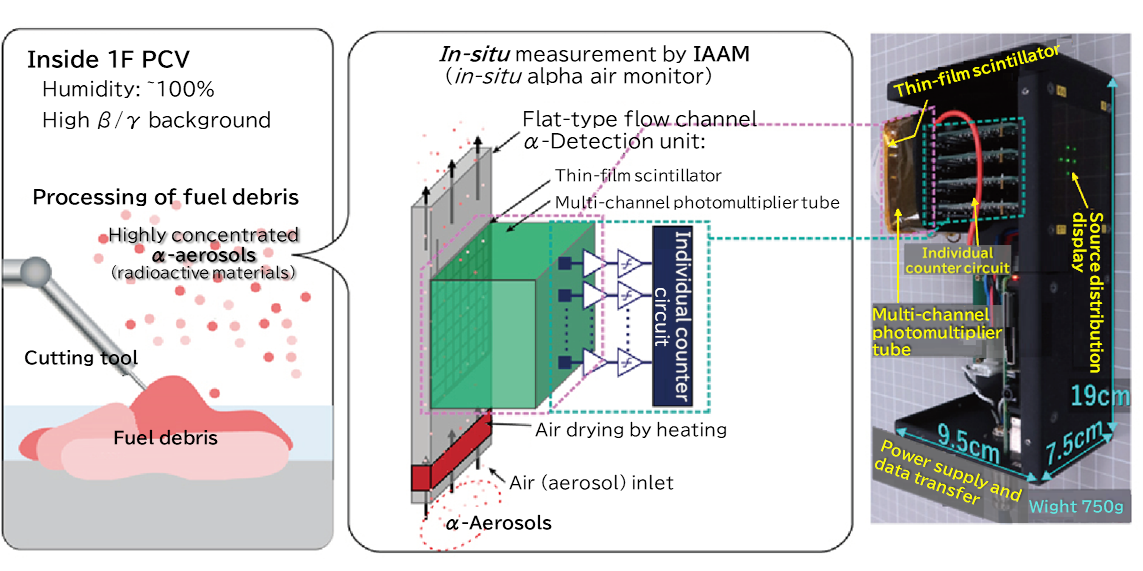

Nuclear facilities use a “dust monitor for α-rays*3”, a device to collect particles on filter paper and measure using a semiconductor detector for α-rays, for radiation monitoring to prevent internal exposure of workers. As dust monitors for α-rays measure the total radioactivity of α-aerosols collected on filter paper, the measured values need to be differentiated against time (or subtracted) to obtain the concentration in the air. Therefore, dust monitors cannot monitor radioactivity in real time. Also, if a large amount of particles are generated by fuel debris retrieval work, filter paper used to collect dust will soon clog up.

Radiation dose rates inside the PCV of the Fukushima Daiichi Nuclear Power Station (1F-PCV) are very high, and frequent replacement of filter paper is not practical. Therefore, a measurement method that does not rely on filter paper different from the conventional “dust monitor for α-rays” will be required. Further, radiation detectors tend to malfunction or become faulty in a high dose rate and high humidity environment, and a system to cope with such an environment will also be required.

To that end, the research group developed the In-situ Alpha Air Monitor (IAAM), a system that enables measuring concentrations of extremely highly concentrated α-aerosols in real time without using filter paper (Figure 2). The IAAM reliably functions in high dose rate and high humidity environments. Also, it can measure α-aerosols with radioactivity concentrations up to 3.2 × 102 Bq/cm3 (more than 30 times the estimated radioactivity concentration inside 1F-PCV, and more than 108 times the Pu concentration limit in controlled areas). In-situ real-time monitoring of α-aerosol concentrations during fuel debris retrieval work will facilitate prevention of internal exposure of workers, greatly improving the safety of the operation.

Figure 2 Comparison of conventional dust monitor (left) and IAAM (right)

In the IAAM, the air is dried using a heater at the flow channel inlet, and α-rays are measured by a detector placed perpendicular to the flat-type flow channel. The detector consists of a thin-film scintillator and multi-channel photomultiplier tube, and signals from multiple channels are individually counted to reduce the chance of counting less than actual.

[Research background and purpose]

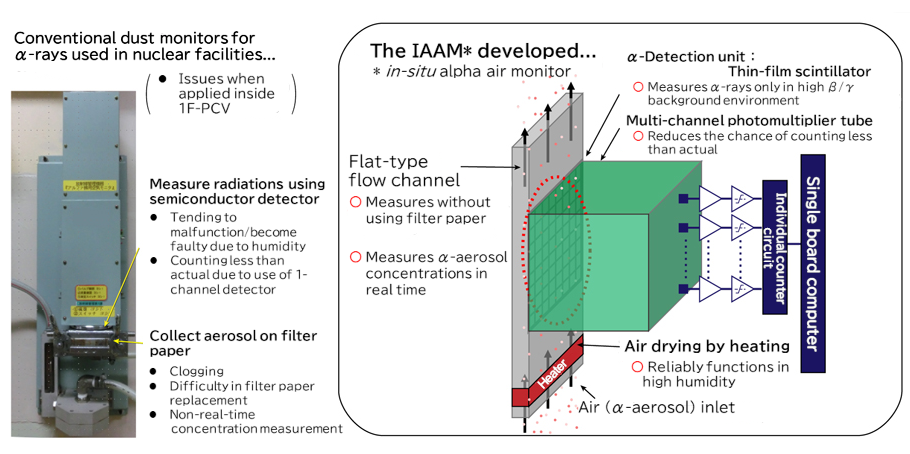

For the decommissioning of the 1F, full systematic retrieval of fuel debris from damaged cores will start in the near future. In the retrieval, fuel debris is to be cut into smaller pieces using cutting tools and lasers, and that is expected to cause minute fragments (microparticles: aerosols) to scatter into the air inside the PCV. Looking at the percentage of effective dose for inhaled aerosols originating from fuel debris (degree of internal exposure) calculated based on the radioactivity 10 years after the accident at the 1F (Unit 2), it can be seen that α-emitters*4 (shown in red) contribute far more than β/γ-emitters*4 (shown in blue) (Figure 3). For that reason, fuel debris retrieval work will have to be carefully performed while monitoring the generation amount and concentrations of α-aerosols with large effective dose coefficients when inhaled*5, while also taking measures to contain them. However, no systematic study on how to monitor α-aerosols inside the 1F-PCV has been made to date.

Figure 3 Percentage of effective dose when inhaled, calculated based on the radioactivity inventory of the 1F (Unit 2)

Since the percentage of α-emitters (shown in red) is large, it is important to contain and monitor them.

For example, cameras have been improved to have excellent radiation resistance in recent years, but if a large amount of α-aerosols are generated while cutting fuel debris, images obtained by a camera will likely become unclear and it will be difficult to estimate the amount of α-aerosols by such images alone. It may be possible to measure aerosols using an exhaust monitor installed at the exhaust device of the 1F-PCV, but different from in-situ real-time monitoring at the cutting site, measurements made by such a method will have a time lag from generation to detection of α-aerosols. For that time lag, when an abnormally high radioactivity concentration is detected, it is possible that a large amount of α-aerosols have already been generated and workers have already inhaled them, leading to unexpected internal exposure of the workers.

Accordingly, the research group summarized as below the four requirements (and reasons therefor) for monitoring α-aerosols near fuel debris cutting sites inside the 1F-PCV, designed and prototyped a measuring device to meet the requirements, and evaluated its performance.

- (1) Reliably functions in a highly humid environment :

(water is injected into the 1F-PCV, and as a result inside the 1F-PCV is highly humid (~100%) and water shields α-rays) - (2) Measures α-aerosols without using filter paper :

(there is a need to measure the concentrations of airborne radioactive materials in real time instead of measuring the total amount of α-aerosols collected on filter paper) - (3) Measures highly concentrated α-aerosols :

(generation of highly concentrated α-aerosols is anticipated during fuel debris cutting work) - (4) Selectively measures α-aerosols :

(there is a need to measure α-aerosols only even inside the 1F-PCV which is a high radiation doze environment with highly concentrated β/γ-aerosols coexisting)

[Research content and results]

The research group designed and prototyped the IAAM that met the requirements above (Figures 1 and 2). Below is a summary of the mechanisms of the IAAM to address the requirements and the verification results of their effects.

(1) The air to be measured is dried by a heater at the flow channel inlet, which successfully maintained the detector unit dry even when air with a humidity of more than 90% was introduced. By this, malfunction or failure of the detector due to humidity is prevented. In addition, aerosol itself is dried at the same time, effectively eliminating the concern over water droplets being suctioned or moisture shielding α-rays.

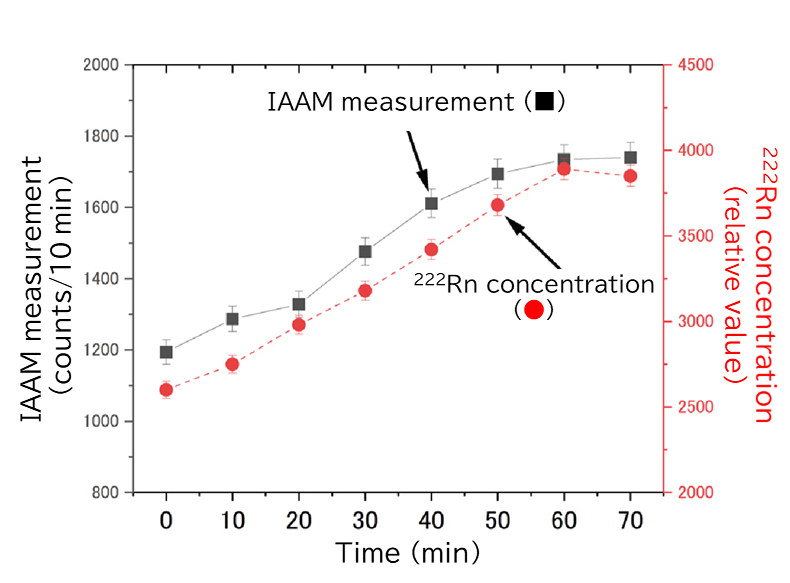

(2) A “flat-type” flow channel with a channel width sufficiently narrower than the travel distance of α-rays was adopted and an α-ray detector was installed perpendicular to the flow channel, which enabled in-situ measurement without using filter paper. As a result of evaluating the performance of the device using the radioactive aerosol production system (patent granted in Europe) held by Hirosaki University, it was demonstrated that the measuring system using the “flat-type” flow channel above was able to measure α-aerosol concentrations (measured as Rn concentrations in the evaluation verification) in the air in real time (Figure 4). In addition, the flow channel is placed vertically and the stack effect due to heating is utilized to introduce the air to be measured without using a mechanical pump, reducing the possibility of mechanical failure of the measuring system.

Figure 4 Measurement results of α-aerosols using IAAM

The values measured by the IAAM smoothly followed the Rn concentrations (α-aerosol concentrations) in real time.

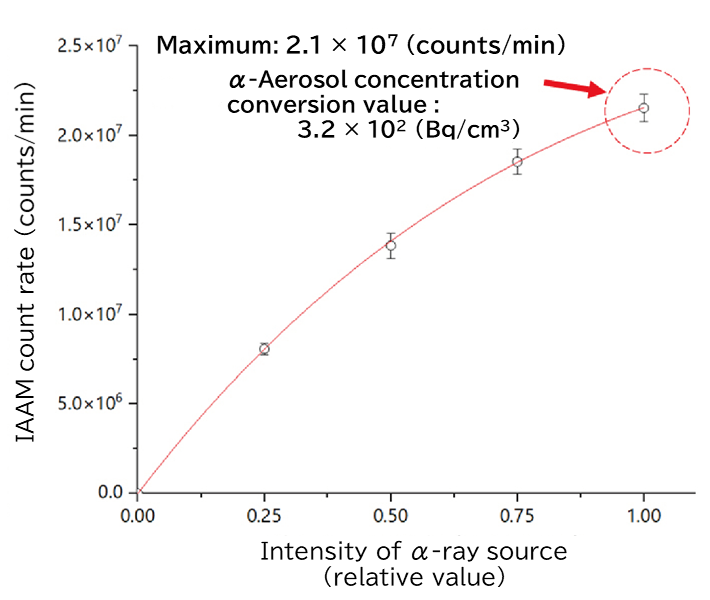

(3) Combining a thin-film scintillator*6 and multi-channel photomultiplier tube*7, signals are measured for each channel to reduce the chance of counting signals less than the actual or impacts of possible detector insensitivity. It was verified that this technique enables measurement up to 3.2 × 102 Bq/cm3 (more than 30 times the estimated radioactivity concentration inside the 1F-PCV, and more than 108 times the regulatory Pu concentration limit in Japan) (Figure 5).

Figure 5 Evaluation of the α-aerosol detection performance of the IAAM by a response test using a high intensity α-ray source

The IAAM can measure highly concentrated α-aerosols more than 30 times the estimated concentration inside the 1F-PCV.

(4) The thickness of the thin-film scintillator was set to a thickness that is sensitive to α-rays only, and the threshold of signal processing was optimized for selective measurement of α-rays. As a result, the IAAM was demonstrated to be able to selectively measure α-rays (α-aerosols) only in a high γ-ray (100 mSv/h) environment without being affected by the γ-rays.

[Significance of the research and future course of action]

The IAAM developed in this project enables in-situ monitoring of α-aerosol concentrations even near fuel debris cutting work areas inside the 1F-PCV. In addition, its maximum measurable concentration is sufficiently higher than the estimated concentration inside the 1F-PCV, and it can keep monitoring even when α-aerosols with unexpectedly high radioactivity concentrations are generated. These features of the IAAM allow implementing measures to reduce internal exposure of workers and swift provision of information to neighboring communities should such a need arise. Ahead of the full systematic fuel debris retrieval, the decommissioning team is about to start detailed investigations inside the PCV and trial retrieval of fuel debris. These operations are planned to be performed near an opening of the PCV, and retrieved fuel debris is to be handled in a glove box*8 or other safe handling devices. α-Aerosols are likely to be generated during such work as well, and in-situ monitoring will prove useful.

The research group of this project has been doing research focusing on the demonstration of measurement principles and techniques. In the future, the group will further improve the system, while exchanging information with TEPCO, aiming at implementation and operation of the system in the actual environment of the 1F. Also, in Japan, the decommissioning of nuclear fuel facilities will become more active in the future. Similar to the fuel debris cutting work at the 1F, dismantling of equipment to which nuclear fuel materials are attached will cause α-aerosols to scatter. However, such dismantling work will be carried out manually, instead of using remote controlled machines. The IAAM’s ability to measure highly concentrated α-aerosols in real time is expected to greatly contribute to improving safety of decommissioning worksites, not just the 1F. With a view to applying the system to such worksites, the research group will continue with the research and development of the IAAM system.

[Glossary]

- *1 Fuel debris retrieval work

In the accident at the Fukushima Daiichi Nuclear Power Station, nuclear fuel, metal materials, concrete and other substances melted and reacted under high temperatures and then were cooled down to form solid fuel debris. Currently, considerations are given to “trial retrieval” using robot arms and other machines. However, full systematic fuel debris retrieval that is to take place in the future may require applying various machining techniques such as mechanical cutting machines and laser cutting devices. - *2 α-Aerosol

In this report, α-aerosols refer to airborne α-emitting radioactive nanoparticles that are generated when cutting melted and fell nuclear fuel materials and fuel debris. Compared to β- or γ-emitting aerosols, α-aerosols have larger internal exposure impacts when inhaled into the human body. Therefore, if they happen to leak outside the PCV, that may lead to internal exposure of workers and local residents. - *3 Dust monitor for α-rays

A dust monitor is a device to measure airborne radioactive material concentrations in the work environment. A dust monitor for α-rays is a dust monitor exclusively designed to measure α-rays. In general, they are structured to collect airborne particles on filter paper and measure radiations emitted from the collected particles using a radiation detector. - *4 Emitter (α-emitter, β-emitter, γ-emitter)

Atoms that emit radiations are called radioisotopes or radionuclides. Radionuclides that emit α-rays, β-rays, or γ-rays are called α-emitters, β-emitters, or γ-emitters, respectively. - *5 Effective dose coefficient

In the accident at the Fukushima Daiichi Nuclear Power Station, nuclear fuel, metal materials, concrete and other substances melted and reacted under high temperatures and then were cooled down to form solid fuel debris. Currently, considerations are given to “trial retrieval” using robot arms and other machines. However, full systematic fuel debris retrieval that is to take place in the future may require applying various machining techniques such as mechanical cutting machines and laser cutting devices. - *6 Thin-film scintillator

A fluorescent substance that emits light (scintillation light) when radiation hits it is called a scintillator. Scintillation light is converted into electrical signals to measure the number of incident radiations and energy. Scintillators are sensitive to α-rays, β-rays, γ-rays, or neutrons in some cases. For the thin-film scintillator, a scintillator was made into a thin film to be sensitive to α-rays only, using the difference in the permeability of radiations. - *7 Multi-channel photomultiplier tube

Among devices to convert scintillation light into electric signals (electrons), those that have a function to internally multiply the electric signals (electrons) are called photomultiplier tubes. A multi-channel photomultiplier tube is a planar array of multiple photomultiplier tubes (multi-channeled). - *8 Glove box

A glove box is a box to handle radioactive materials, etc. in a closed space while visually observing them. The general structure of a glove box is a stainless steel box with a clear acrylic or reinforced glass panel on one side, and the panel has rubber gloves attached to it. An operator can manipulate the target or device inside through the gloves.

Related articles

- Where can I find information on decommissioning?

- Is it possible to visualize radiations? Also, is there a way to understand the situation of contamination inside the Fukushima Daiichi NPS buildings?

- What is a cesium ball?

- What happened to the inside of the reactor pressure vessel and storage vessel after the accident?