Information on treated water and decommissioning

(2023)

QWhat kind of measures against leakage of contaminated water are taken on the premises of the Fukushima Daiichi Nuclear Power Station (1F)?

AA research team led by JAEA developed a fiber-type monitor that enables real-time measurement with distinguishing β-rays and γ-rays. Verification using the 1F site and simulated contaminated water demonstrated that this monitor successfully detects β-emitter strontium (90Sr) in water distinguished from γ-rays.

Real-time monitoring of β-rays in water will contribute to early detection of contaminated water leakage and reduced burden on workers without relying on sampling and analysis of water in the drainage.

This monitor was installed at the 1F by the Tokyo Electric Power Company Holdings, Inc., and started operating on January 31, 2020.

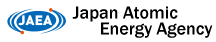

Figure 1 The appearance of the fiber-type monitor and the logic to detect β-rays based on the travel distance of radiations in water

• A resin thickness to shield β-rays from radioactive cesium and to detect strong β-rays from strontium-90 ( 90Sr ; actually, it is β-rays emitted from yttrium-90 ( 90Y ), a decay product of 90Sr ) only was selected.

• Only β-rays can be detected from the difference in radiations shielded by the stainless steel layer.

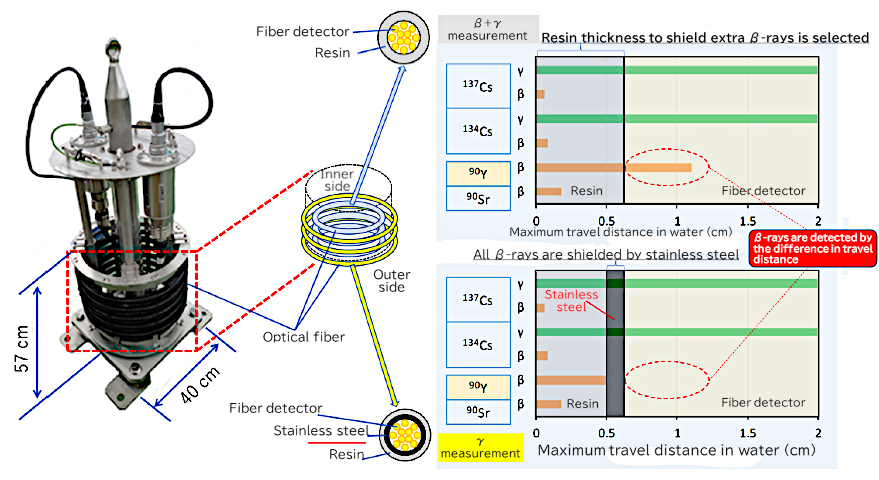

Contaminated water at the decommissioning site of the 1F contains not only γ-emitters 134Cs and 137Cs but also β-emitter 90Sr. For their relatively long travel distances in the air and water, γ-rays can be easily measured directly. However, β-rays have short travel distances and it is difficult to measure them directly, and there has been strong demand for real-time β-ray monitoring technology to be established. One of the technical challenges is the fact that the existing (prototype) drainage monitor cannot easily tell the difference between β-rays and γ-rays, making it difficult to distinguish contaminated water (leaked from nuclear buildings) from rainwater that contains 134Cs or 137Cs (originating from radioactive fallout) (Figure 2). In addition, the current radiation control is to do on-site sampling and analysis of drainage water when a monitor detects radioactivity above a certain warning level, and to dam up the drainage until no leakage of contaminated water is confirmed. This process takes time, and more swift means for checking leakage has been wanted. Further, detailed assay of β-emitters requires on-site sampling of water and measuring the samples in laboratories using special devices such as a liquid scintillation counter, which incurs labor, time, and cost.

Figure 2 Schematic illustration of radioactive material detection by the conventional monitor and improved monitor

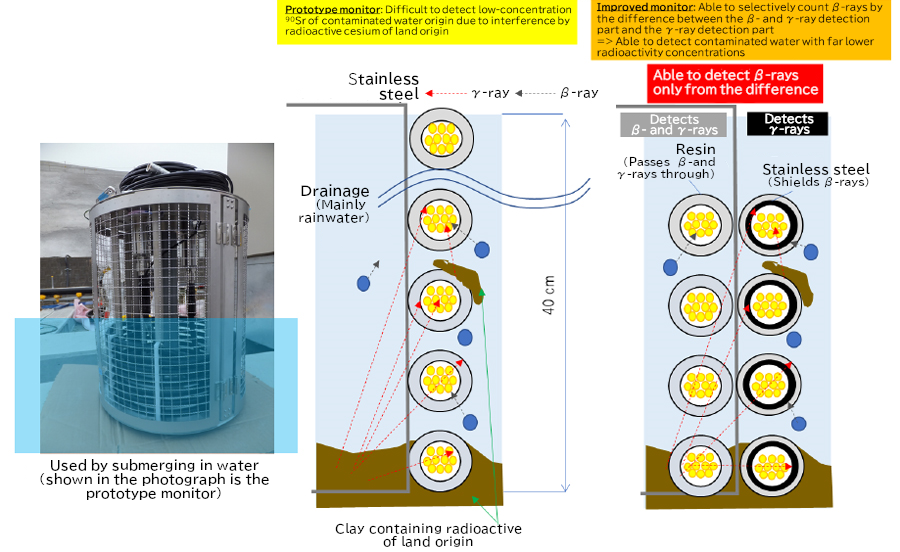

As an underwater radiation measurement technique, use of a method using plastic scintillation fiber*1 started in the environment around the 1F immediately after the accident. This technique uses plastic scintillators sensitive to β-rays and γ-rays shaped into strings, and is characterized by its ability to identify the incident positions of radiations (Figure 3). In addition, for its large and flexible detection area, this technique has been used for pre- and post-decontamination areal measurement in the environment since the accident at the 1F1), and for its waterproofness, it has been used in bottom water monitoring and other purposes2). For the purpose of applying the technology of plastic scintillation fiber used in the environment to the detection of contaminated water at the 1F, JAEA developed a fiber-type monitor that enables real-time measurement with distinguishing β-rays and γ-rays3).

Figure 3 The principle and appearance of the fiber-type monitor

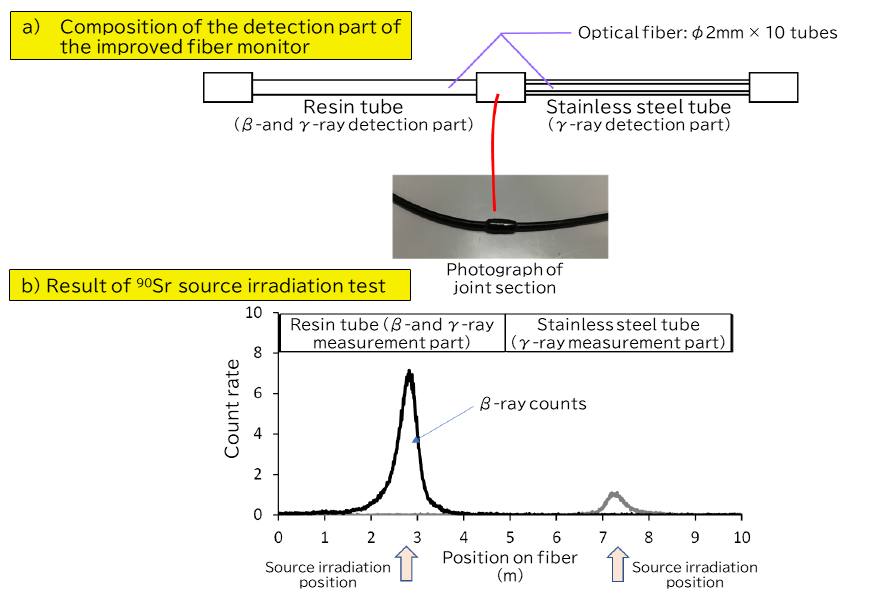

To distinguish between β-rays and γ-rays, taking into account the travel distance of β-rays of 90Sr*2, JAEA devised a detector that has a part to measure γ-rays only by covering one side of 10-m fibers by a stainless steel tube that shields β-rays and detects β-rays from the difference from the resin part (Figure 4a). As shown in Figure 1, compared to β-rays from 134Cs or 137Cs, β-rays emitted by 90Y, a descendant nuclide of 90Sr, have relatively high energy and travel a longer distance in water. The tube thickness is selected to capture such characteristics of β-rays of 90Sr and to shield interfering β-rays of 134Cs or 137Cs. Figure 4 also shows the results of measuring a 90Sr source at the middle section of the resin tube part (β- and γ-ray measurement part) and stainless steel tube part (γ-ray measurement part). As can be seen, the β-ray count rate at the stainless steel tube part was smaller than the resin part (Figure 4b).

Figure 4 Composition of β- and γ-ray distinguishing detector and results of 90Sr source irradiation test

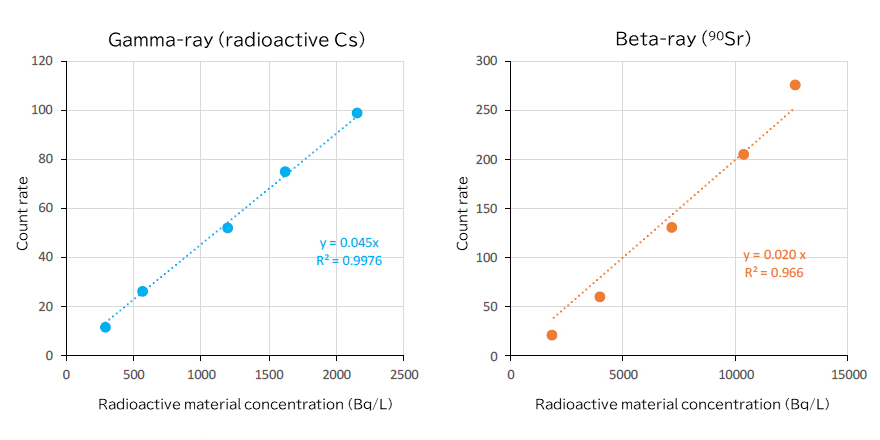

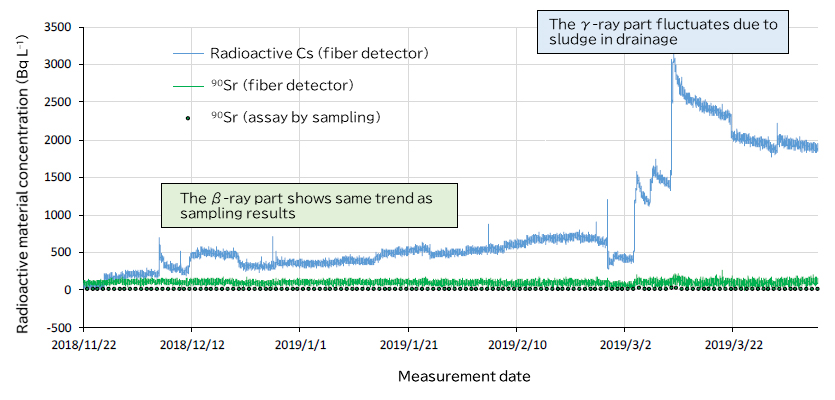

The developed device was calibrated using a standard solution of a known radioactivity concentration for quantification at the actual 1F site. As a result, count rates showed a good linear correlation with radioactive material concentrations in the range of 100 Bq/L to 10000 Bq/L, demonstrating that the device can be used to quantity radioactivity in this concentration range (Figure 5). The calibrated device was installed in the actual drainage of the 1F to check its durability and to evaluate the reliability of measurement results. The evaluation method was to compare monitoring results with the results of measurement by the conventional method, i.e., sampling water from the drainage and measuring the concentration of 90Sr in a laboratory (Figure 6). As a result of the comparison, it was found that the measurements of the fiber-type monitor showed a similar trend as the measurements by sampling, and the fiber-type monitor is applicable as a reliable radiation monitor. In response to this result, the TEPCO HD manufactured practical-use monitors, installed them at the 1F site, and started operating them on January 31, 2020.

Figure 5 Result of calibration using contaminated water of known radioactivity concentration

Figure 6 Result of monitoring in 1F drainage (example)

The technology developed in this project enabled on-site real-time monitoring of 90Sr in contaminated water, which used to be difficult in the past. With it, if there is a possibility of contaminated water leakage in the drainage, 90Sr concentrations in the drainage can be checked using a PC installed in an office, instead of sampling water from the drainage and analyzing it in a laboratory. This will greatly contribute to swift decisions on contaminated water leakage and reduced workload on workers. In addition, this technology is applicable to other nuclear power stations as a monitor of water discharged from them. JAEA plans to provide any necessary support in the case of failure of the fiber-type monitor after installation or any issues that may emerge. JAEA will continue to cooperate and contribute to the decommissioning of the 1F through research and development.

[Glossary]

- *1 Plastic scintillation fiber (fiber-type monitor):

It was developed in the early 1980s for the purpose of measuring the travel distance of fast charged particles in the field of high energy physics. In the late 1990s, it was combined with the Time-of-Flight (TOF) method*3 and applied as a technique to measure dose rate distributions inside reactors and facilities. The core material*4 of plastic scintillation fiber is plastic scintillator that is sensitive to radiations and generates light when irradiated. A plastic scintillation fiber can identify the position of the generated light from the difference in time the light reaches photomultiplier tubes located at both ends of the fiber. Since it is string-shaped, it has a large contact area in water and enables measurement with relatively high efficiency. The fiber-type detector can be manufactured at a relatively low cost especially for the detector part, yet enables highly efficient measurement of radioactive materials in water for the reason above. Plastic scintillation fiber was jointly developed by Japan Radiation Engineering Co., Ltd. and JAEA. - *2 β-rays emitted by 90Sr:

90Y generated as a β-decay product of 90Sr emits high energy (2.28 MeV) β-rays. - *3 Time-of-Flight (TOF) method:

The TOF method is a general method to measure the distance, which derives the distance from a light source using the time of flight (delay time) of light from being emitted from the light source, reflected at the target object, and reaching the sensor and the speed of light (3×108 m/s). In plastic scintillation fibers, the position is determined by the difference in time for light to reach photomultiplier tubes at both ends. - *4 Core material:

A general optical fiber cable has a three-layer structure consisting of the core (or core material), clad outside the core, and coating to cover the clad. By using a core with a higher refractive index than the clad, light travels through the core only through total reflection and refraction. In the fiber-type monitor, a plastic scintillation fiber sensitive to radiations is used as the core material.

Related articles

- Where can I find information on decommissioning?

- Is it possible to visualize radiations? Also, is there a way to understand the situation of contamination inside the Fukushima Daiichi NPS buildings?

- What is a cesium ball?

- What happened to the inside of the reactor pressure vessel and storage vessel after the accident?

References

- 眞田幸尚(2016): 福島第1原子力発電所事故後におけるプラスチックシンチレーションファイバを用いた環境計測, 光学, vol. 45, 300-305.

- 眞田幸尚, 髙村善英, 卜部嘉, 土田清文, 西澤幸康, 山田勉, 佐藤義治, 平山弘克, 西原克哉, 伊村光生, 石田睦司, 石橋聖, 佐瀬隆聡, 鈴木元和, 森英治, 米澤重晃, 鳥居建男(2014): 水底のin-situ放射線分布測定手法の開発, JAEA-Research 2014-005. https://doi.org/10.11484/jaea-research-2014-005

- 眞田幸尚, 山田勉, 佐藤義治, 西澤幸康, 石橋聖, 渡辺将久, 鳥居建男(2016): プラスチックシンチレーションファイバ測定技術の福島第一原子力発電所における汚染水管理への応用, JAEA-Research 2016-011. https://doi.org/10.11484/jaea-research-2016-011